John Deere 955 Hydrostatic Drive 32 Hp 4 Wheel Drive Review

3E Tractor engine

3E Tractor engine

3025E

The i.642-Fifty (100.2 cu in.) displacement, liquid-cooled 3TNV88F-EPJT1 Yanmar® diesel engine provides 18. kW (24.4 hp) to the 3025E.

| Model | Number of | Engine | Rated rpm | Gross engine hp* | Gross engine ps* | PTO hp |

| 3025E | 3 | i.642 L (100.two cu in.) | 2400 | 18.2 kW (24.iv hp) | 24.vii | 13 kW (17.four hp) |

*Engine kW (hp), gross SAE J1995: 18.ii (24.4) at 2400 rpm, PS

Displacement, 50 (cu in.): 1.642 (100.2)

3032E

The one.642-L (100.two cu in.) displacement, liquid-cooled 3TNV88C-NJT Yanmar diesel fuel engine provides 22.nine kW (30.seven hp) to the 3032E.

| Model | Number of | Engine | Rated rpm | Gross engine hp* | Gross engine ps* | PTO hp |

| 3032E | 3 | 1.642 L (100.2 cu in.) | 2500 | 22.9 kW (30.7 hp) | 31.2 | xviii.6 kW (25 hp) |

*Engine kW (hp), gross SAE J1995: 22.9 (thirty.seven) at 2500 rpm, PS

Displacement, L (cu in): 1.642 (100.2)

3038E

The 1.568-L (95.68 cu in.) displacement, turbocharged, liquid-cooled 3TNV86T-NJT Yanmar diesel engine provides 27.4 kW (36.7 hp) to the 3038E.

| Model | Number of | Engine | Rated rpm | Gross engine hp* | Gross engine ps* | PTO hp |

| 3038E | three | 1.568 L (95.68 cu in.) | 2500 | 27.iv kW (36.vii hp) | 37.two | 22.4 kW (30 hp) |

*Engine kW (hp), gross SAE J1995: 27.4 (36.7) at 2500 rpm, PS

Displacement, L (cu in.): 1.568 (95.68)

The engine uses the latest technologies to optimize fuel economy, ameliorate control and accurateness, and reduce environmental affect. The common runway system (CRS) optimizes fuel economy and reduces operating costs comparted to engines not using CRS engineering. High-pressure injection atomizes fuel into finer particles which fire more completely. It results in improved fuel economy and a lower cost of functioning.

The electronic command unit (ECU) provides optimum fuel command and accuracy. ECU monitors and controls the engine. It continuously monitors engine conditions and adjusts the fuel delivery appropriately to ensure optimum functioning and emissions.

The engine comes with an afterward-treatment system. The system operates automatically. The exhaust filter consists of a diesel particulate filter (DPF) which captures particulate affair (PM) contained in the exhaust gas. Using a natural cleaning process, most of the PM trapped in the exhaust filter is eliminated by the oestrus of the exhaust stream generated by normal apply. In situations of depression temperature, engine speed, or load factor, an agile cleaning bike is initiated. In this cleaning wheel, the frazzle gas temperature is raised by injecting boosted fuel during the exhaust stroke of normal vehicle operation to the diesel fuel oxidation goad (DOC).

Later on many hours of use, the exhaust filter may require an ash removal service.

DPF cleaning

Depending on the load that the tractor is under, likewise as ambience temperature, humidity, and engine speed, the DPF may build up with particulate affair, thus requiring cleaning. Filter cleaning is adamant by one of three factors:

- A prescribed time-based estimation of needed filter cleaning

- Medico/DPF pressure sensors

- A particulate matter buildup estimation based on load conditions

In one case i of the three conditions has been met, filter cleaning will occur.

There are iii different types of filter cleaning processes:

- Passive filter cleaning

- Active filter cleaning

- Parked filter cleaning

Passive filter cleaning

Passive filter cleaning occurs naturally when the engine is generating enough heat to oxidize particulate matter. This automated process occurs continuously during normal operating weather. No tractor icons or symbols appear on the display during passive filter cleaning.

NOTE: Passive filter cleaning requires no operator interest, and there is no interruption to tractor operation.

Agile filter cleaning

If atmospheric condition (temperature, load, or speed) for passive filter cleaning cannot be accomplished, and then PM is removed using active filter cleaner.

To achieve the required weather condition, exhaust temperature direction (ETM) manages the initiation and elapsing of active filter cleaning. ETM tin adapt numerous engine parameters and/or inject a pocket-sized quantity of fuel into the frazzle stream for a short duration. The fuel turns to vapor and chemically reacts with the catalysts in the DOC to create rut to oxidize the PM.

It is important to note that at no time is the fuel in the Md/DPF ignited, and there is no flame inside the DOC/DPF.

Like passive filter cleaning, agile filter cleaning requires no operator involvement, and there is no interruption to tractor operation.

Parked filter cleaning

In some instances where passive and agile filter cleaning have non fully cleaned the PM from the system, a parked filter cleaning may need to take place. In general, the only fourth dimension a parked filter cleaning will need to occur is when automatic filter cleaning has been disabled for an extended menstruum of time and multiple warnings to engage filter cleaning were ignored or if the tractor has been used during light load atmospheric condition. Additionally, when the automatic filter cleaning process has been deliberately interrupted multiple times, or if active filter cleaning has failed numerous times due to a failed component, a parked filter cleaning may be requested. In these rare instances the operator will have to park the tractor and outset the filter cleaning process.

The parked filter cleaning process needs to exist activated based on usage and performance of the tractor. The procedure will take approximately xxx minutes. See the operator'due south manual for more details.

This system constantly monitors the soot level of the tractor; making sure the tractor is always in top performance condition. This ensures high operation at all times.

Note: Number of hours since last regeneration and soot level percentage are viewable on LCD display.

Key features of the engine are:

- Economical bandage-in-block cylinder pattern for skilful cooling and long life

- Directly fuel injection

- Improves starting

- Injects fuel directly on top of pistons for more efficient combustion

- Develops more horsepower per liter (gallon) of fuel than indirect injection engines

- Aluminum alloy pistons are lightweight to reduce connecting rod bearing loads and provide good heat transfer characteristics

- Pattern permits tighter tolerances and neutralizes expansion of the piston, which reduces accident-by and racket from piston slap

- Meridian rings are higher on the piston and a thinner head gasket is used to greatly reduce the book of unburned waste product gases and increase combustion efficiency

- Timing gears and injector bulldoze gears have a helical contour to reduce engine racket

- Car-drain fuel arrangement

- In that location is no need to prime the system if the tractor runs out of fuel

- The organisation will self-prime number the injection pump, lines, and injectors, providing fast fuel recovery for easier starting

- High-capacity lubrication system provides filtered oil, nether force per unit area, to all engine bearings for long life

- Cardinal start and shutoff eliminate fuel shutoff knob

- Electric solenoid shuts the fuel supply off immediately when key is turned off, which replaces the need to pull a fuel shutoff lever similar many older tractors

- Fuel filter with replaceable element

- H2o separator with additional replaceable filter element

- Run into-through coolant recovery tank permits operator to cheque coolant level without removing radiator cap

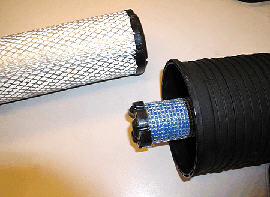

Dry-type air cleaner

Dry-type air cleaner

- Dry-type air cleaner with safety element

- Dual element design for added engine protection

- Piece of cake to service

- Hood can be easily opened without tools for full access to the engine

- Like shooting fish in a barrel access to engine check and fill points on the right-hand side of the tractor by removing the side panels.

Yanmar is a trademark of Yanmar Visitor Express.

Source: https://www.deere.com/en/tractors/compact-tractors/3-series-compact-tractors/3032e/

0 Response to "John Deere 955 Hydrostatic Drive 32 Hp 4 Wheel Drive Review"

Postar um comentário